TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

10

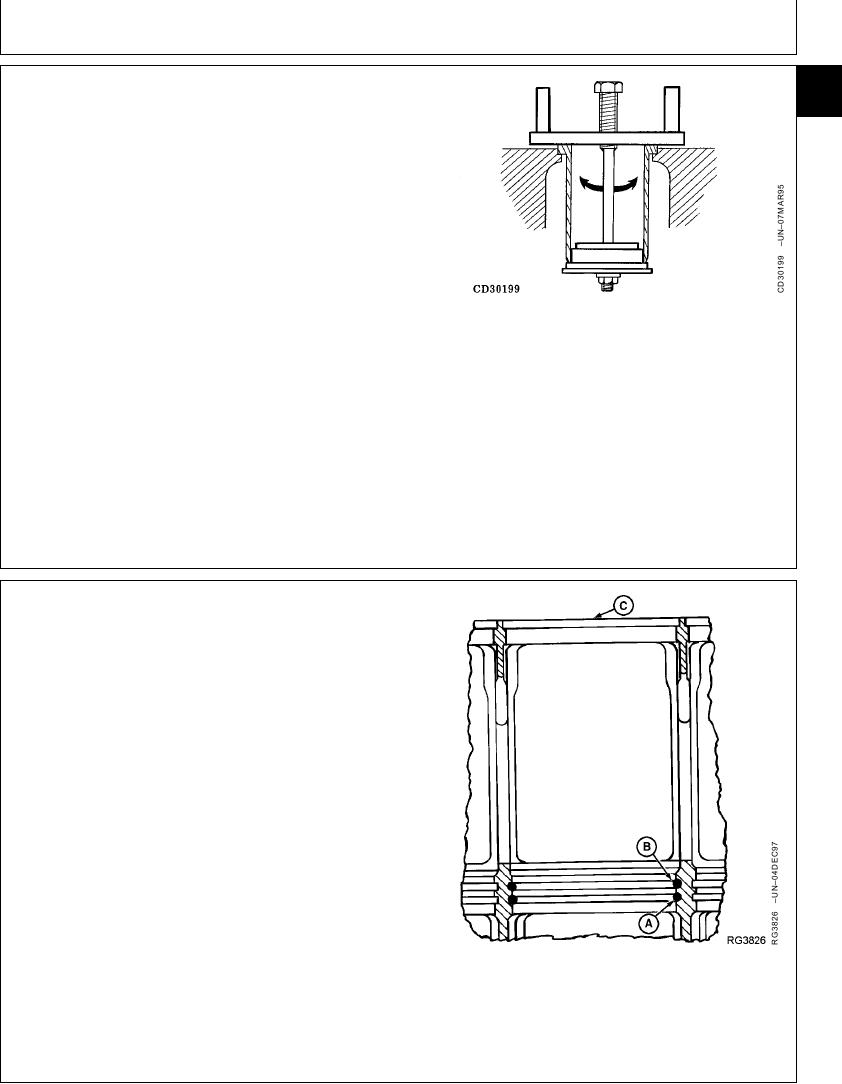

4. If liner height is above specification, check cylinder

53

block for burrs on liner support flange or incorrect

counterbore depth. If burrs are present, apply lapping

compound to liner flange shoulder in the block, then

install liner and turn to left and right using KCD10001or

JDG1145 Cylinder Liner Puller to rub off enough

material to seat liner as necessary.

IMPORTANT: ONE LINER SHIM ONLY may be

installed under each liner flange. If liner

requires more than one shim, install a

new liner or cylinder block.

KCD10001 Shown

5. If liner height is no more than 0.08 mm (0.003 in.)

below top deck of block, install one liner shim under

liner flange.

NOTE: Two shim sizes are available; 0.05 mm (0.002 in.)

and 0.10 mm (0.004 in.).

RG,10,DT7392 1911NOV973/3

INSTALL PACKING ON CYLINDER LINER

AND O-RINGS IN BLOCK

IMPORTANT: DO NOT use oil or hand cleaner soap

on cylinder liner packing or O-rings.

Petroleum products will cause the red

(or white) O-ring to swell, which may

result in O-ring damage during liner

installation.

1. Pour AR54749 Soap Lubricant into a suitable

container.

2. Dip O-rings in AR54749 Soap Lubricant.

3. Install the black O-ring (A) in the lower O-ring groove

in the cylinder block (C).

4. Install the red (or white) O-ring (B) in the upper O-ring

groove in the cylinder block.

A--Black O-Ring

B--Red or White O-Ring

C--Cylinder Block

Continued on next page

RG,10,DT7391 1911NOV971/2

13-166