TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

REMOVE, INSPECT, AND INSTALL PISTON

10

49

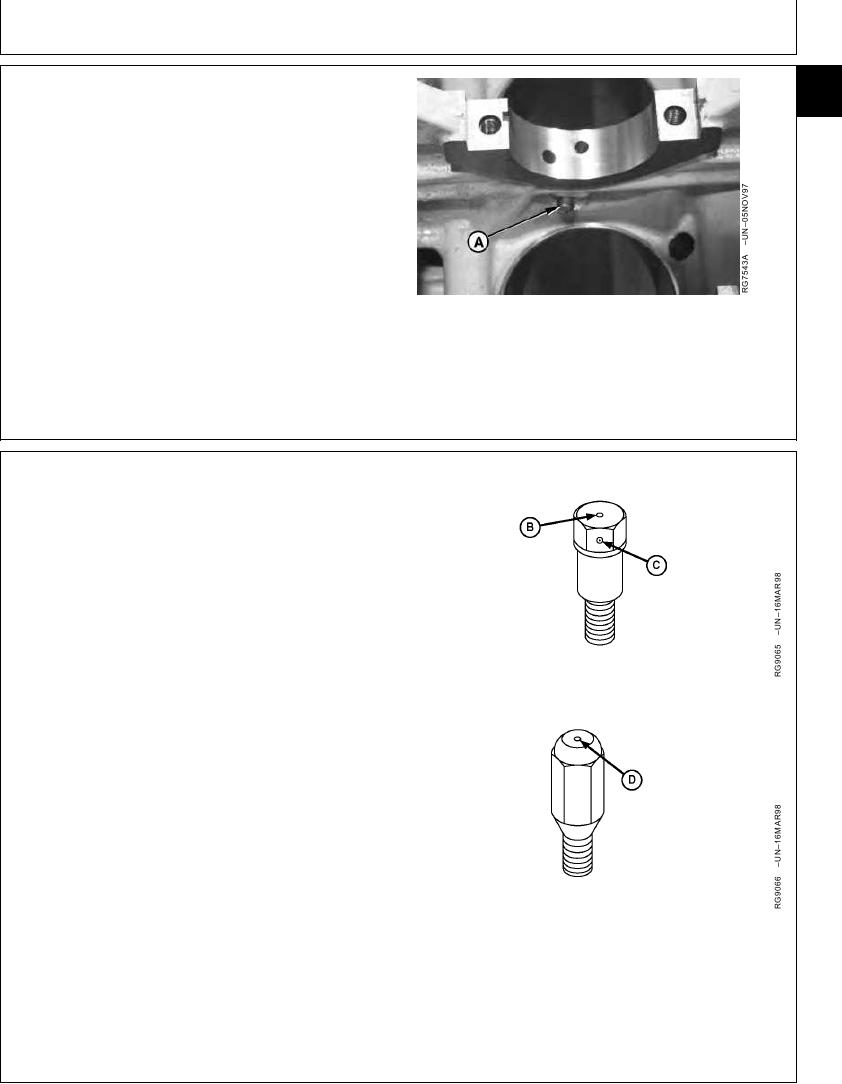

COOLING ORIFICES

IMPORTANT: A piston cooling orifice failure could

cause damage to pistons, piston pins,

rod pin bushings and liners. If a piston

cooling orifice is left out, low or no oil

pressure will result.

1. Remove and clean each piston cooling orifice (A) to

make sure it is not plugged or damaged. Replace if

questionable.

RG,10,DT7394 1911NOV971/2

NOTE: If equipped with early design orifice (B), add a

punch mark (C) to each orifice as shown. This is

not necessary on later design orifice (D) because

of its different shape. Adding a punch mark to

orifice (B) will also prevent cooling jets from being

mistakenly used on 300-Series Engines.

&pwrtec; Engines use a larger orifice diameter

cooling jet for proper lubrication and cooling of

piston skirts.

2. Install and tighten orifices.

Piston Cooling Orifice--Specification

Diameter ....................................................................... 1.4 mm (0.055 in.)

Piston Cooling Orifice--Specification

Torque ............................................................... 11 Nm (8 lb-ft) (96 lb-in.)

3. If removed, install new oil and water galley plugs as

required.

B--Early Design Orifice

C--Punch Mark

D--Later Design Orifice

RG,10,DT7394 1911NOV972/2

13-162