TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

10

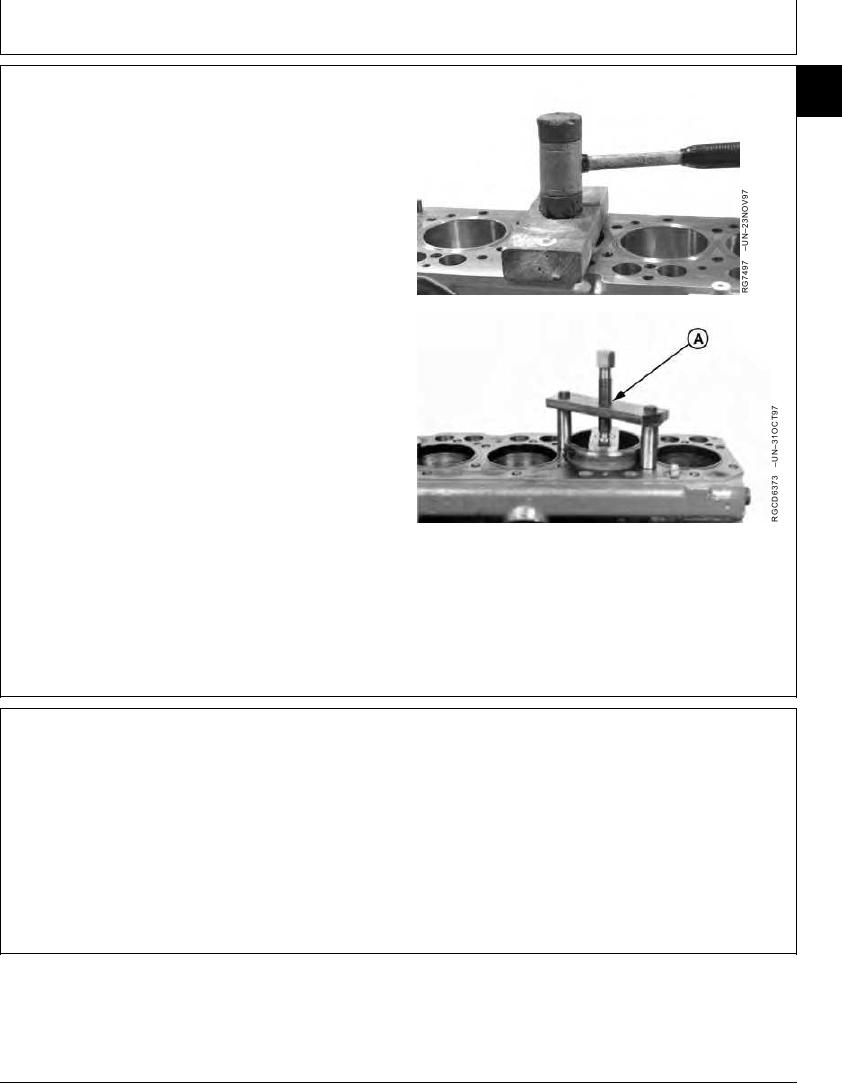

2. A resistance will be felt when cylinder liner is aligned in

55

pilot bore. Finish seating liners using clean, hardwood

block and mallet. Gently tap hardwood block over top

of cylinder liner with mallet. KCD10001 (A) or JDG1145

Puller may also be used to seat liners.

NOTE: Cylinder liner will protrude over top of cylinder

block more than normal due to uncompressed

packings and O-rings.

IMPORTANT: If you suspect a packing may have

sheared or displaced during liner

installation, remove and examine the

liner and packing assembly. If no

damage is found, check packings for

proper position. Resoap packings, and

reinstall liner assembly.

3. Hold liners in place with large flat washers and cap

screws. Turn cap screws snug but do not tighten.

4. Clean cylinder liner bores with waterless hand cleaner

after installation. Wipe dry with clean towels.

5. Apply clean engine oil to liner bores immediately to

prevent corrosion.

A--KCD10001 Liner Puller

RG,10,DT7390 1911NOV972/2

ASSEMBLE PISTON AND CONNECTING ROD

IMPORTANT: If a new piston and liner assembly is to

be installed, DO NOT remove piston

from liner. Push piston out of liner

bottom only far enough to install piston

pin.

1. Lubricate piston pin and bushing with clean engine oil.

Continued on next page

RG,10,DT7389 1911NOV971/2

13-168