TM 5-3805-294-23-1

0021

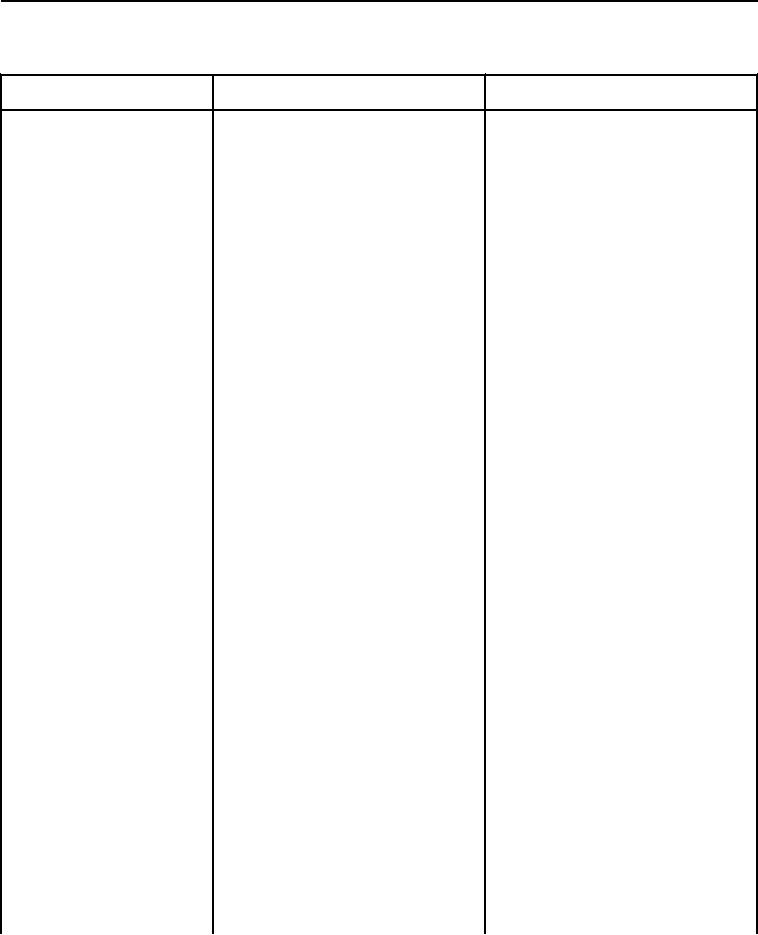

Table 1. DTC 100.01 - Engine Oil Pressure Signal Extremely Low - Continued.

Test or Inspection

Corrective Action

Malfunction

Visually inspect engine wiring

1.

If damaged, replace engine

3.

Engine Wiring

harness for pinched or melted

wiring harness. (Volume 4,

Harness Damaged.

wires between engine wiring

WP 0510) Restore machine to

harness connector P04

original condition and operate

(Volume 5, WP 0800, Figure

engine through normal speed

56) and engine wiring harness

and load (TM 5-3805-294-10).

connector J03. (Volume 5,

(Volume 5, WP 0794) Clear

WP 0800, Figure 48)

and refresh DTCs. (Volume 3,

WP 0362)

2.

If not damaged, proceed to

Malfunction 4.

Visually inspect engine oil

1.

If damaged or has loose pins,

4.

Engine Oil Pressure

pressure sensor for damaged

replace engine oil pressure

Sensor Damage or

housing, damaged O-ring, and

Has Loose Pins.

sensor. (Volume 3, WP 0417)

loose pins. (Volume 5,

Restore machine to original

WP 0800, Figure 56)

condition and operate engine

through normal speed and

load (TM 5-3805-294-10).

(Volume 5, WP 0794) Clear

and refresh DTCs. (Volume 3,

WP 0362)

2.

If not damaged and does not

have loose pins, proceed to

Malfunction 5.

Visually inspect engine oil

1.

If damaged, replace engine.

5.

Engine Oil Pressure

pressure sensor engine

Sensor Engine

(Volume 3, WP 0410) Restore

housing for damage. (Volume

Housing Damaged.

machine to original condition

5, WP 0800, Figure 56)

and operate engine through

normal speed and load (TM

5-3805-294-10). (Volume 5,

WP 0794) Clear and refresh

DTCs. (Volume 3, WP 0362)

2.

If not damaged, proceed to

Malfunction 6.

1.

Connect engine wiring

6.

Engine Oil Pressure

harness connector P04 to

Sensor Input

removed engine oil pressure

Voltage Out of

Limits.

sensor. (Volume 5, WP 0800,

Figure 56)

2.

Connect negative battery

cable. (Volume 4, WP 0521)

0021-4