TM 5-2420-230-24-1

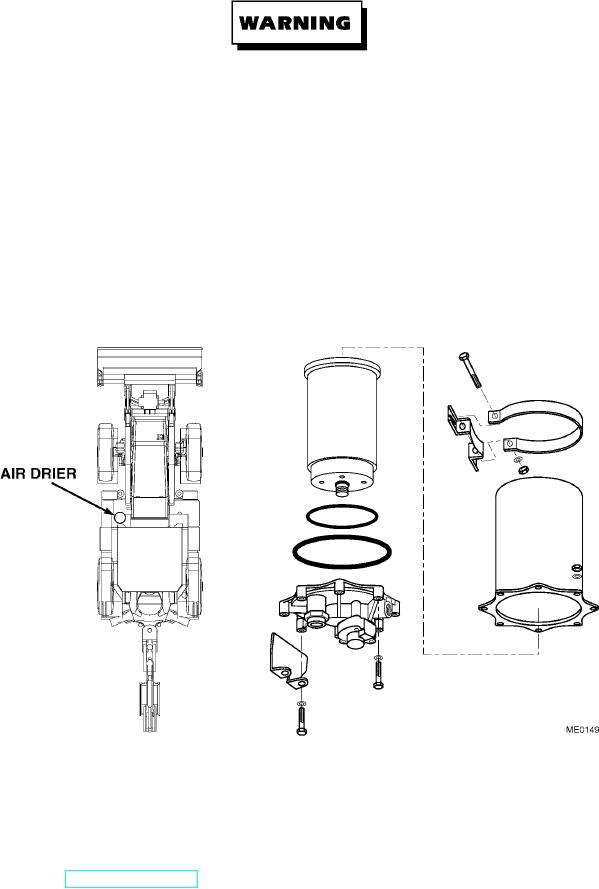

a. Removal.

Ensure air pressure is drained to 0 psi (0 kPa) before taking off any air components. If pressure is not

released, components could blow off and harm personnel. The IHMEE air system is pressurized to 119 psi

(820 kPa). Do not drain air from a tank with any part of body in air spray path. Skin embolisms and/or debris

in eyes can occur from released pressure. Failure to comply may result in injury or death to personnel.

NOTE

Tag all hoses, wires, and tubes and note their positions before removal.

Remove cable ties as necessary.

Cap and plug all tubes, hoses, and fittings upon removal.

(1)

Loosen nut and bolt from upper strap.

(2)

Support air drier assembly and remove two nuts, bolts, and washers from drier to mounting bracket.

(3)

Remove air drier assembly from mounting bracket.

b. Installation.

Steps in the installation of the air drier are the reverse of those in the removal procedure, with attention given to the

following point:

Ensure pneumatic connections are correct and secure.

c. Follow-On Maintenance.

(1)

Start engine (TM 5-2420-230-10).

(2)

Check air drier for leaks.

15-17