TM 5-2420-230-24-1

Maintenance & Service Manual

R & HR32000 3 & 6 Speed LD

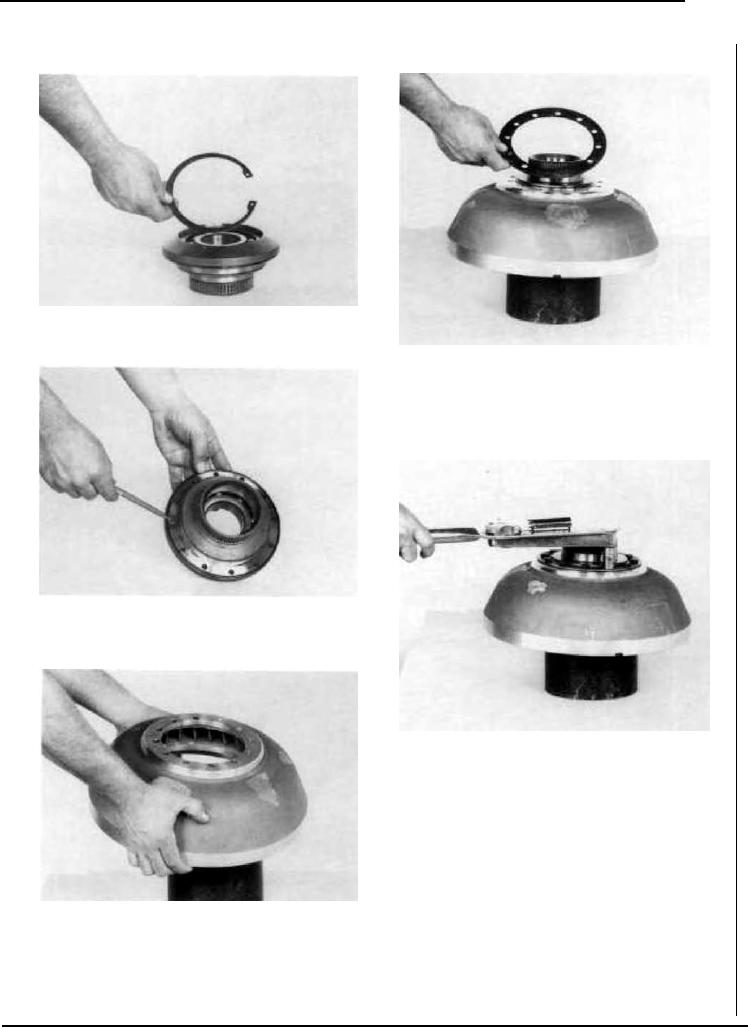

Figure 283

Install bearing retainer ring.

Figure 286

Position backing ring on impeller.

Figure 284

Position new "O" ring on impeller hub.

Figure 287

Install (12) impeller hub special screws to approximately .06

inch (1,5) of seated position. With a calibrated torque wrench,

tighten screws to 40-45 lbs. ft. [54,3-61.0 N.m.] torque. NOTE:

Assembly of impeller to impeller hub must be completed within

a fifteen minute period from start of screw installation. The

screws are prepared with a coating which begins to harden after

installation in the impeller hub holes. If not tightened to proper

torque within the fifteen minute period, insufficient screw

clamping tension will result. The special screw is to be used for

one installation only. If the screw is removed for any reason it

must be replace.

The compound left in the hub holes must be removed with the

proper tap and cleaned with solvent. Dry hole thoroughly and

Figure 285

use a new screw for reinstallation.

Align holes in impeller with holes in impeller hub.

--49--

F-94