TM 5-2420-230-24-2

Injection Pump - Installation (0-88)

Section 0 - Engine Disassembly and Assembly - Group 00

Page 0-72

B Series Shop Manual

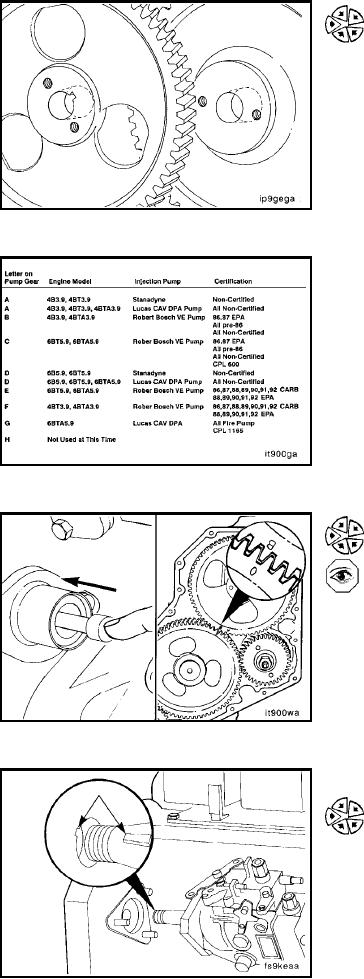

The injection pump drive gear has a tapered bore.

Orient the wide end of the taper toward the engine

(timing marks away). The drive gear for the Nip-

pondenso EP9 and the Bosch P7100 pump does not

have timing marks and must be positioned using the

tapered bore as a reference.

This table must be used to make sure of proper fuel

injection pump-to-engine timing. The critical parts list

(CPL) number from the engine data plate and the Control

Parts List Manual (Bulletin No. 3379133-20) must be used

to determine whether or not the engine is certified, and

if so, what year and regulating agency (EPA or CARB).

Given this information, use the table to determine which

letter on the fuel injection pump drive gear is aligned with

the camshaft gear.

Align the timing marks and set the gear into the housing.

No timing mark alignment is required for the Nippondenso

EP9, or Bosch Inline fuel pumps.

Locked Timed Injection Pump - Installation

(0-89)

Install the pump. Make sure the key doesn't fall into the

gear housing.

NOTE: The keyway in the shaft of new and reconditioned

pumps will be locked in a position corresponding to the

keyway in the drive gear when cylinder number 1 is at TDC.

If the Bosch, Stanadyne or CAV pump was not locked in

this position before removal and a timing tool, Part No.

3377259, is not available for the Bosch pump, refer to

installing an unlocked pump, procedures (0-91 and 0-92).

Refer to Section 5 for the Nippondenso EP9 and Bosch

inline timing procedure.

L-161