TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Flywheel Housing (016-006)

Section 16 - Mounting Adaptations - Group 16

Page 16-17

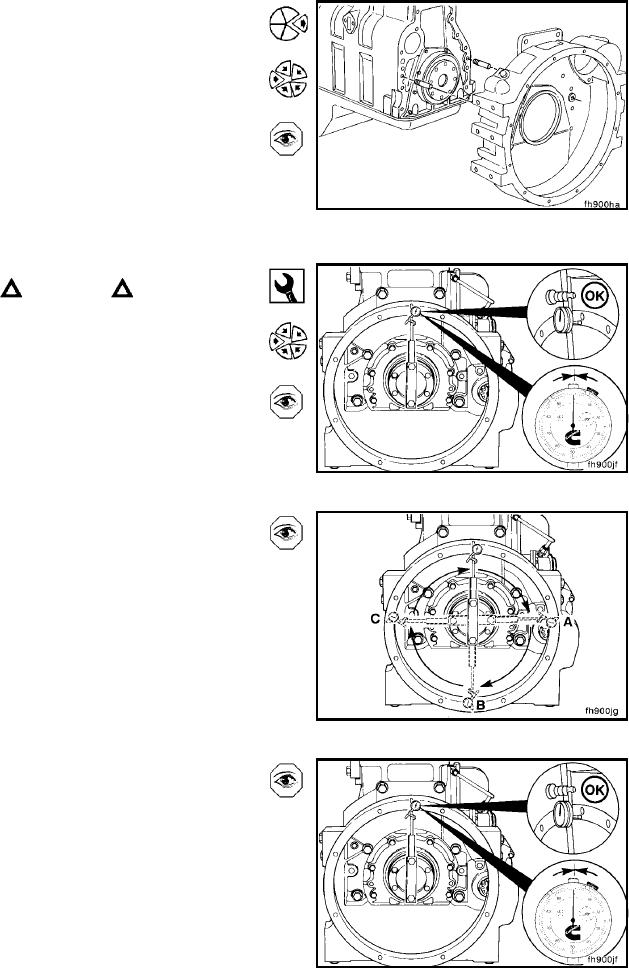

If the intersection point falls outside the shaded area, the

ring dowels must be removed and the housing reposi-

tioned.

NOTE: The ring dowels are not required to maintain con-

centricity of the housing; the clamping force of the

capscrews holds the housing in place.

After the ring dowels are discarded, install the flywheel

housing on the engine.

To position the housing, tighten the capscrews enough to

hold the flywheel housing in place, but loose enough to

allow small movement when struck lightly with a mallet.

Recheck the concentricity. When concentricity is within

specification, tighten the capscrews to the specified torque

value.

CAUTION

The dial indicator tip must not enter the capscrew holes,

or the gauge will be damaged.

Face Alignment

Dial Indicator Gauge, Part No. 3376050

Install the dial indicator gauge, Part No. 3376050, as illus-

trated.

NOTE: The extension bar for the indicator must be rigid for

an accurate reading. It must not sag. Position the indicator

at the twelve-o'clock position. Adjust the dial until the needle

points to zero.

Slowly rotate the crankshaft. Record the readings at the

three-o'clock, six-o'clock, and nine-o'clock positions.

NOTE: The crankshaft must be pushed toward the front of

the engine to remove the crankshaft end clearance each

time a position is measured.

Continue to rotate the crankshaft until the indicator is at the

twelve-o'clock position. Check the indicator to make sure

the needle points to zero. If it does not, the readings will

be incorrect.

L-1345