TM 5-3805-281-24-2

Removal and Installation

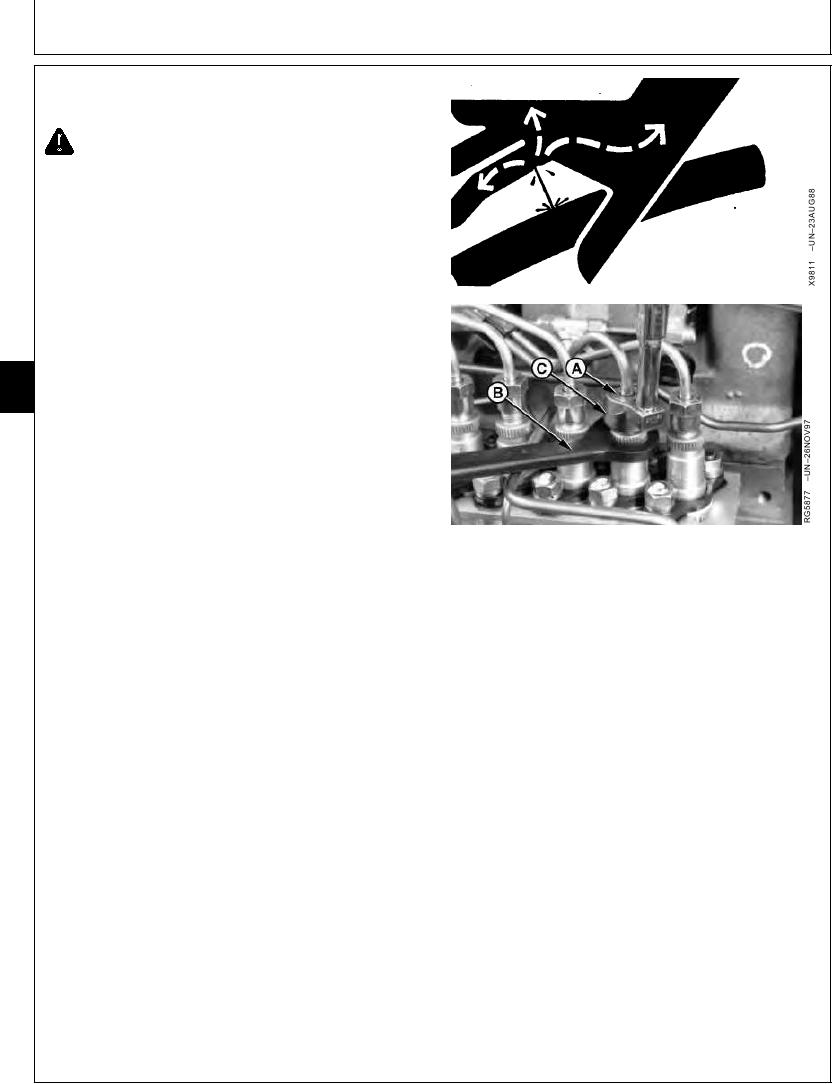

REMOVE FUEL INJECTION NOZZLES

CAUTION: Escaping diesel fuel under pressure

can have sufficient force to penetrate the skin,

causing serious injury. Before disconnecting

lines, be sure to relieve pressure. Before

applying pressure to the system, be sure ALL

connections are tight and lines, pipes, and

hoses are not damaged. Keep hands and body

away from pin holes and nozzles which eject

fluid under pressure. Use a piece of cardboard

or wood, rather than hands, to search for

suspected leaks.

If ANY fluid is injected into the skin, it must be

surgically removed within a few hours by a

04

0400

doctor familiar with this type injury or gangrene

28

may result. Doctors unfamiliar with this type of

injury may call Deere & Company Medical

Department in Moline, Illinois, or other

knowledgeable medical source.

IMPORTANT: Cap or plug all fuel lines as they are

disconnected to prevent dirt and debris

from entering fuel system. Debris in fuel

system can plug injectors which affects

A--Injection Line Nut

engine performance.

B--JDE90 Serrated Wrench

C--JDF22 Crowsfoot Wrench

1. Thoroughly clean area around injection pump and

nozzles, including all line connections, using

compressed air.

IMPORTANT: JDE90 Serrated Wrench (B) MUST BE

used to keep delivery valve fittings

stationary while loosening line nuts. If

delivery valve and barrel housing

rotates while loosening or tightening a

fuel line nut, injection pump delivery

will be altered. Pump must be

recalibrated on a test stand.

2. Disconnect injection line nuts (A) from injection pump

delivery valves using JDF22 Crowsfoot Wrench (C) or

a standard 3/4 in. line wrench and JDE90 Serrated

Wrench (B).

Continued on next page

CED,OUOE024,210

1914MAY981/4