TM 5-3805-281-24-2

Cylinder Head and Valves

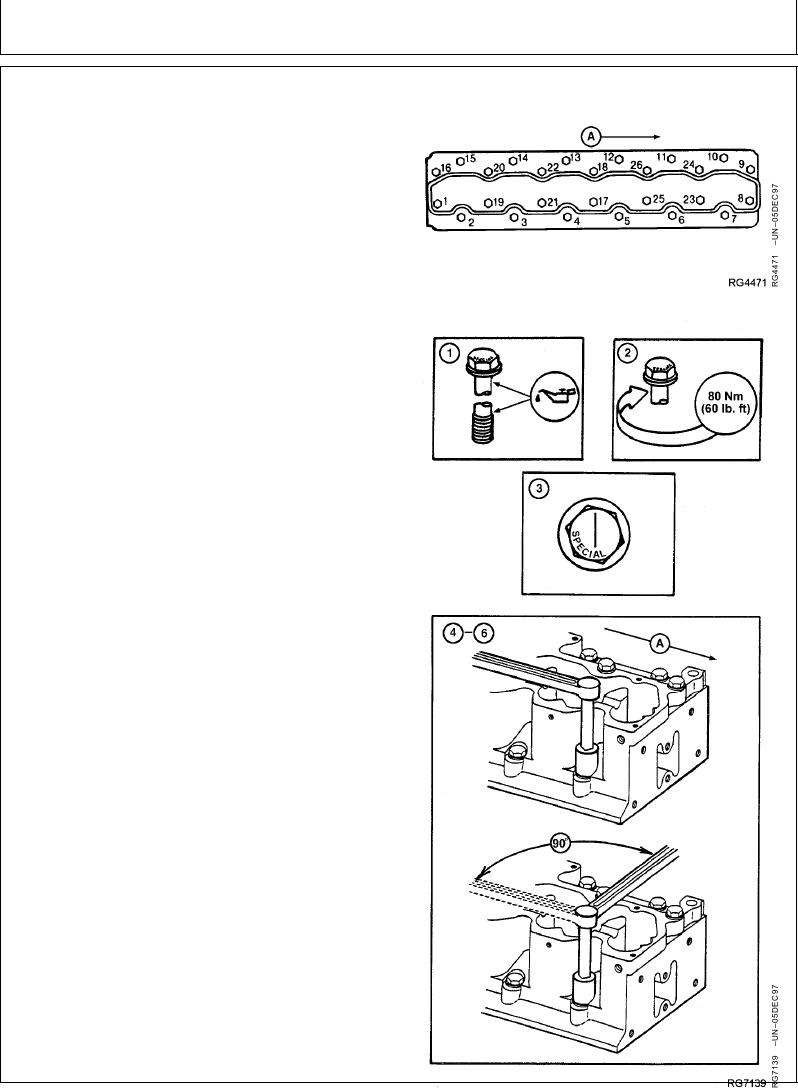

TORQUE-TO-YIELD FLANGED-HEAD CAP

SCREWS--GRADE 180 MARKED "SPECIAL"

Arrow (A) points toward front of engine.

IMPORTANT: DO NOT use multi-viscosity oils to

lubricate cap screws.

1. Lubricate cap screws with clean SAE30 engine oil and

install in their proper locations as outlined previously.

2. Tighten cap screw No. 17 to 80 Nm (60 lb-ft).

Sequentially (start at cap screw No. 1 and proceed

Head Cap Screw Locations

through cap screw No. 26) tighten all cap screws to 80

Nm (60 lb-ft).

3. Using an oil-proof pen, pencil, or marker, draw a line

parallel to the crankshaft across the entire top of each

cap screw head. This line will be used as a reference

mark.

IMPORTANT: If a cap screw is accidentally tightened

more than 90 in any one sequence, DO

NOT loosen cap screw but make

adjustments in the next tightening

sequence.

4. Sequentially (start at cap screw No. 1 and proceed

through cap screw No. 26) turn each cap screw 90.

Line on top of cap screw will be perpendicular to

crankshaft.

5. Again, sequentially (start at cap screw No. 1 and

proceed through cap screw No. 26) turn each cap

screw 90. Line on top of cap screw will now be

parallel to crankshaft.

6. Finally, sequentially (start at cap screw No. 1 and

proceed through cap screw No. 26). Turn each cap

screw 90, SO THAT LINE ON TOP OF CAP SCREW

IS AS CLOSE AS POSSIBLE TO BEING

PERPENDICULAR TO THE CRANKSHAFT. It is not

necessary to obtain the final turn in one swing of the

wrench. TOTAL AMOUNT OF TURN FROM STEPS 4,

5, AND 6 IS 270 5.

Continued on next page

RG,RG34710,1103

1923OCT971/2

Torque-to-Yield Tightening of Head Cap Screws