TM 5-3805-281-24-2

Fuel System

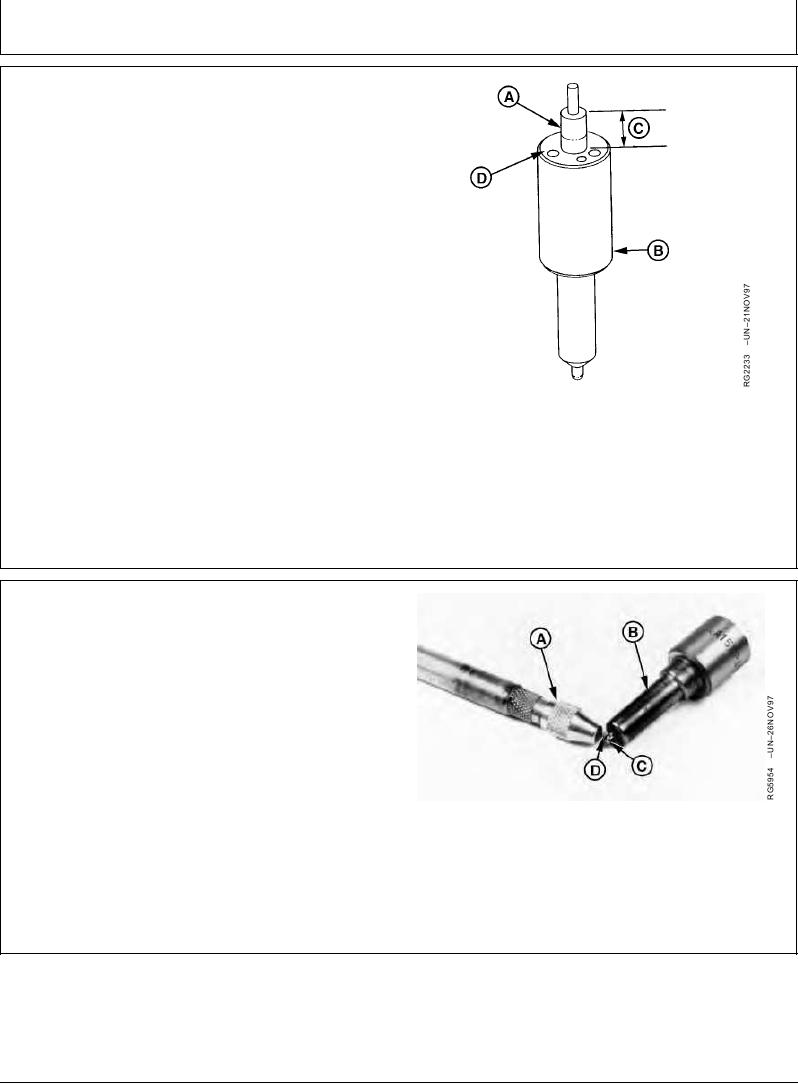

PERFORM NOZZLE SLIDE TEST

NOTE: DO NOT touch lapped surface (D) unless hands

are wet with diesel fuel.

1. Dip nozzle valve (A) in clean diesel fuel.

2. Insert valve in nozzle (B).

3. Hold nozzle vertical and pull valve out about one-third

of its engaged length.

4. Release valve. Valve should slide down (C) to its seat

by its own weight. Always replace a nozzle assembly if

the valve does not fall freely to its seat.

Performing Nozzle Slide Test

A--Nozzle Valve

B--Nozzle

C--Free-Fall Distance

D--Lapped Surface

RG,RG34710,1310

1923OCT971/1

CLEAN SPRAY ORIFICES

1. Begin with cleaning wire (D) 0.07--0.10 mm (0.003--

0.004 in.) from JDF105 Nozzle Cleaning Kit.

NOTE: Stoning wire to provide a flat surface on one side

will help in reaming carbon from clogged hole.

2. Clamp cleaning wire in pin vise (A). Wire should not

protrude from vise more than 0.8 mm (1/32 in.).

3. Insert wire into orifice (C) and rotate.

Cleaning Nozzle Spray Orifices

4. For final cleaning, use cleaning wire 0.03 mm (0.01 in.)

smaller than orifice size. Follow previous steps until

orifices are clean of any carbon deposits.

RG,RG34710,1311

1923OCT971/1