TM 5-3805-281-24-2

Fuel System

RG2248 UN22NOV97

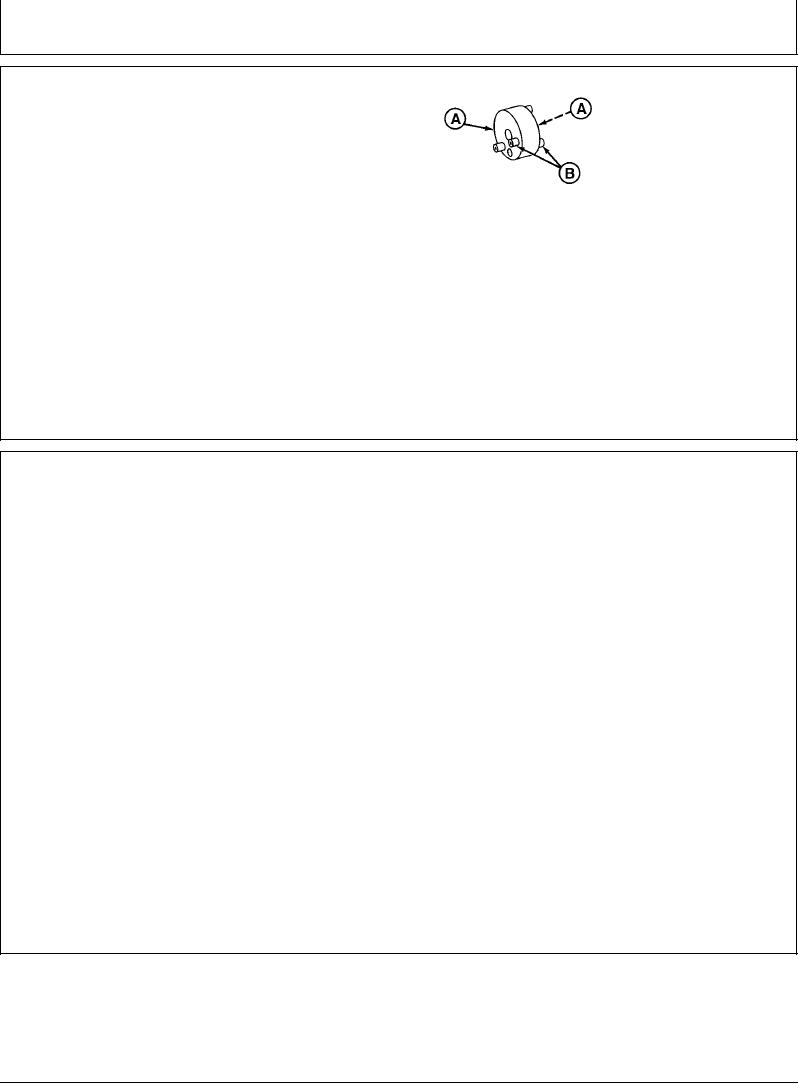

IMPORTANT: Do not lap the machined surfaces (A) of

the intermediate plate in an attempt to

stop fuel leakage at these locations.

Dowels (spring pins) (B) in plate have to

be removed before surfaces can be

lapped. Removing dowels is not

recommended as removal is likely to

Nozzle Intermediate Plate

damage them, and replacement dowels

are not available as service parts.

If leakage is observed, tighten nozzle retaining nut to a

maximum of 79 Nm (58 lb-ft). Replace injection nozzle

if leakage continues.

RG,RG34710,1306

1923OCT972/2

PERFORM CHATTER AND SPRAY PATTERN

TEST

1. Injection nozzle should chatter very softly, and only

when hand lever movement is very rapid (four to six

downward movements per second). Failure to chatter

may be caused by a binding or bent nozzle valve.

2. Until chattering range is reached, the test oil emerges

as non-atomized streams. When lever movement is

accelerated, sprays should be very broad and finely

atomized.

A partially clogged or eroded orifice will usually cause

spray to deviate from the correct angle. Spray will also

be steady rather than finely atomized.

3. Disassemble nozzle for cleaning or reconditioning if it

fails to chatter or spray properly.

RG,RG34710,1307

1923OCT971/1