TM 5-3805-281-24-2

Fuel System

INJECTION NOZZLE OPENING PRESSURE

SPECIFICATIONS

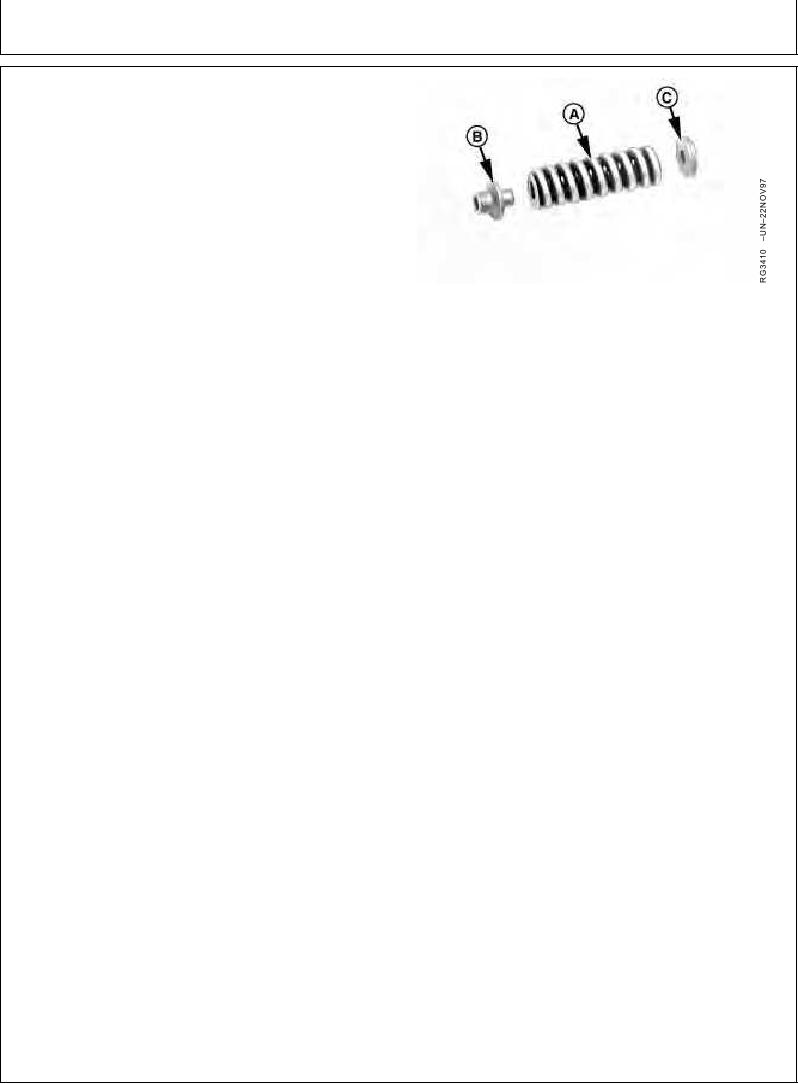

A new nozzle or a used nozzle with a new spring (A),

should open at approximately the following pressures. A

used nozzle that has been rebuilt with a new spring

and/or valve should be reset to same pressures as a new

nozzle. New nozzle opening pressures are:

New Injection Nozzle (All Tip Sizes)--Specification

Opening Pressure .................................. 29 000 kPa (290 bar) (4200 psi)

Injection Nozzle Spring and Pressure Adjusting Shims

minimum

On nozzles which have been in service, spring and spring

seat (B) will have taken a normal set. In this case,

opening pressure is satisfactory if it meets or exceeds

used nozzle minimum opening pressure given below, but

does not exceed new opening pressure given above.

Used nozzle minimum opening pressures are:

Used Injection Nozzle (All Tip Sizes)--Specification

Opening Pressure .................................. 26 200 kPa (262 bar) (3800 psi)

minimum

IMPORTANT: ALWAYS use John Deere nozzle

adjusting shims which are specially

hardened. Other shims will not be

satisfactory.

Shims (C) of different thicknesses are available for

changing opening pressure adjustment. Each 0.05 mm

(0.002 in.) of shim thickness changes opening pressure

approximately 700 kPa (7 bar) (100 psi).

If nozzle opening pressures are not correct, disassemble

injection nozzles (as described in this group) and change

shims until nozzles open at proper new nozzle pressure

given above.

The difference in nozzle opening pressures between

cylinders in an engine should not exceed 350 kPa

(3.5 bar) (50 psi).

RG,RG34710,1305

1923OCT971/1