TM 5-3805-281-24-2

Fuel System

PERFORM NOZZLE LEAKAGE TEST

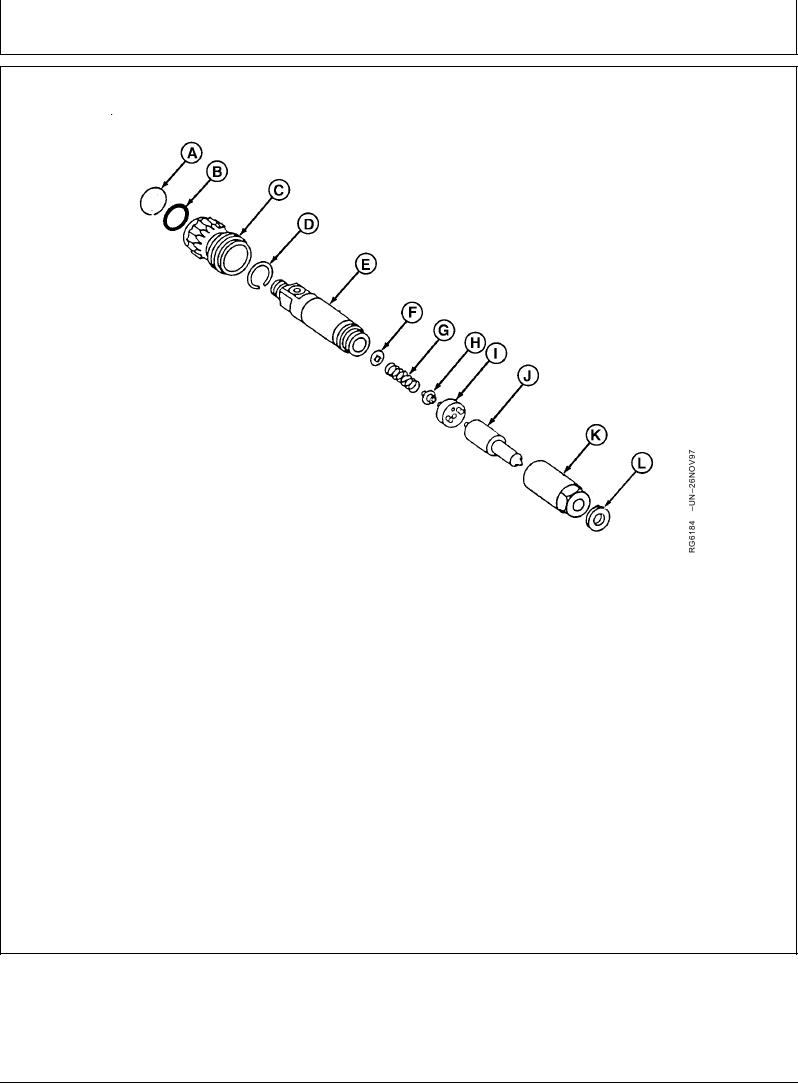

Bosch Injection Nozzle (Nippondenso Similar)

A--Upper Snap Ring

D--Lower Snap Ring

H--Spring Seat

L--Washer

(Bosch only)

E--Nozzle Holder

I--Intermediate Plate

B--Gland Nut O-Ring

F--Shim

J--Nozzle and Valve

C--Gland Nut

G--Nozzle Valve Spring

K--Nozzle Retaining Nut

3. Check for leakage around nozzle retaining nut (K)

1. Wipe nozzle dry.

thread connection with nozzle holder (E).

2. Bring pressure up slowly to 1970 kPa (20 bar)

Leakage indicates a bad seat either between nozzle

(285 psi) below the opening pressure. Watch for an

and intermediate plate (I) or between nozzle holder

accumulation of fuel from spray orifice, indicating a

and intermediate plate.

bad seat.

If nozzle drips within 10 seconds, replace nozzle

and valve (J).

Continued on next page

RG,RG34710,1306

1923OCT971/2