TM 5-3805-281-24-2

Hydraulic System

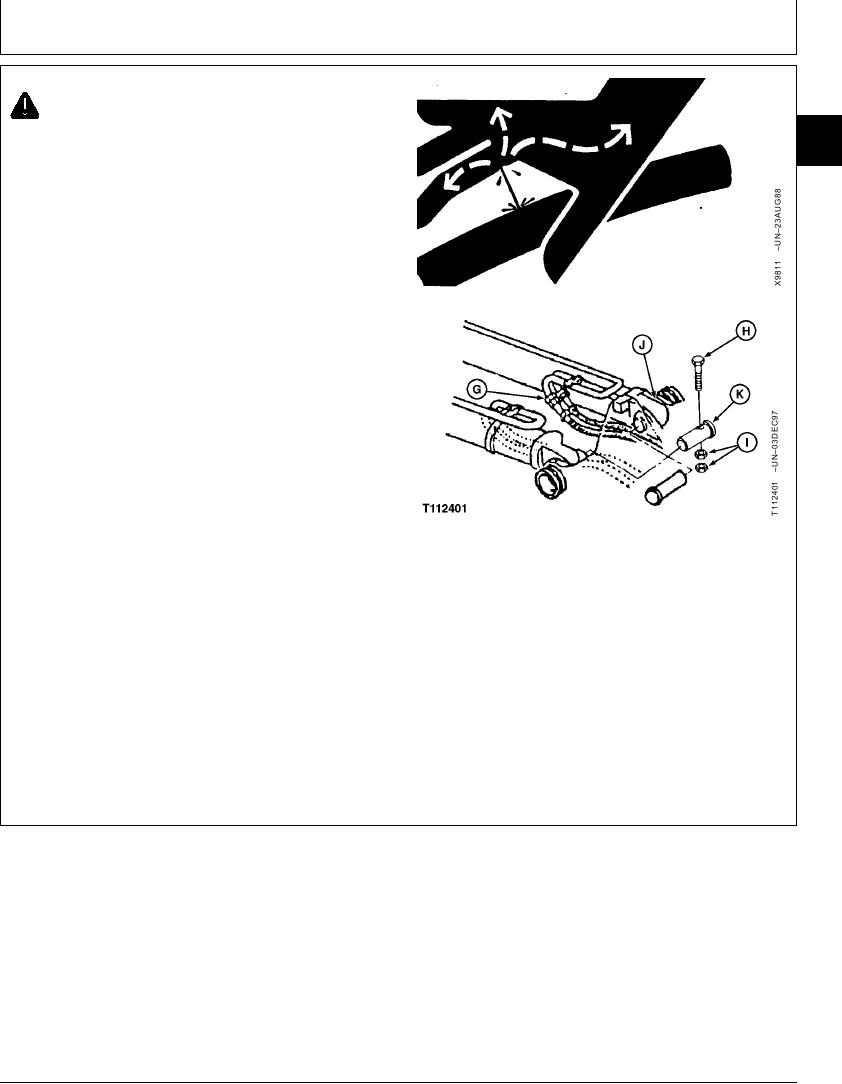

CAUTION: To avoid injury from escaping fluid

under pressure, stop engine and relieve the

33

pressure in the system before disconnecting

3360

hydraulic or other lines. Tighten all connections

151

before applying pressure.

9. Disconnect lines (G) from cylinder.

10. Take notice of washer (J) locations for assembly.

Remove parts (H--K) to remove cylinder.

11. Repair or replace cylinder.

12. Install washers (J) equally on each side of cylinder

head end to get minimum amount of clearance in

joint.

13. Align pin bores so dust seals are not damaged as

boom cylinder-to-frame pin (K) is installed.

Tighten nuts (I) against each other, not the retainer.

Cap screw (H) must be free to turn in hole.

Boom Cylinder-to-Frame Pin M20 Cap Screw Nut--Specification

G--Rod End-to-Boom Section Bottom Port Line

Torque ....................................................... 540 Nm (400 lb-ft) tighten nut

--Head End-to-Boom Section Top Port Line

against nut, not the retainer

H--M20 Cap Screw

I--M20 Nut (2 used)

J--Washer (As Required)

14. Connect lines (G).

K--Boom Cylinder-to-Frame Pin

Continued on next page

CED,OUOE026,9

1918JUN984/5

19-178