TM 5-3805-281-24-2

Hydraulic System

IMPORTANT: Trapped air suddenly compressed in a

cylinder is heated and ignites the oil

33

used for assembly causing cap seal and

3360

ring damage. Start with cylinder rod

152

retracted and the rod end filled with

clean oil. Connect the cylinder head end

and lines. Operate function to slowly

extend rod. Procedure will eliminate

most of the air and reduce the

possibility of damage.

15. Start the engine.

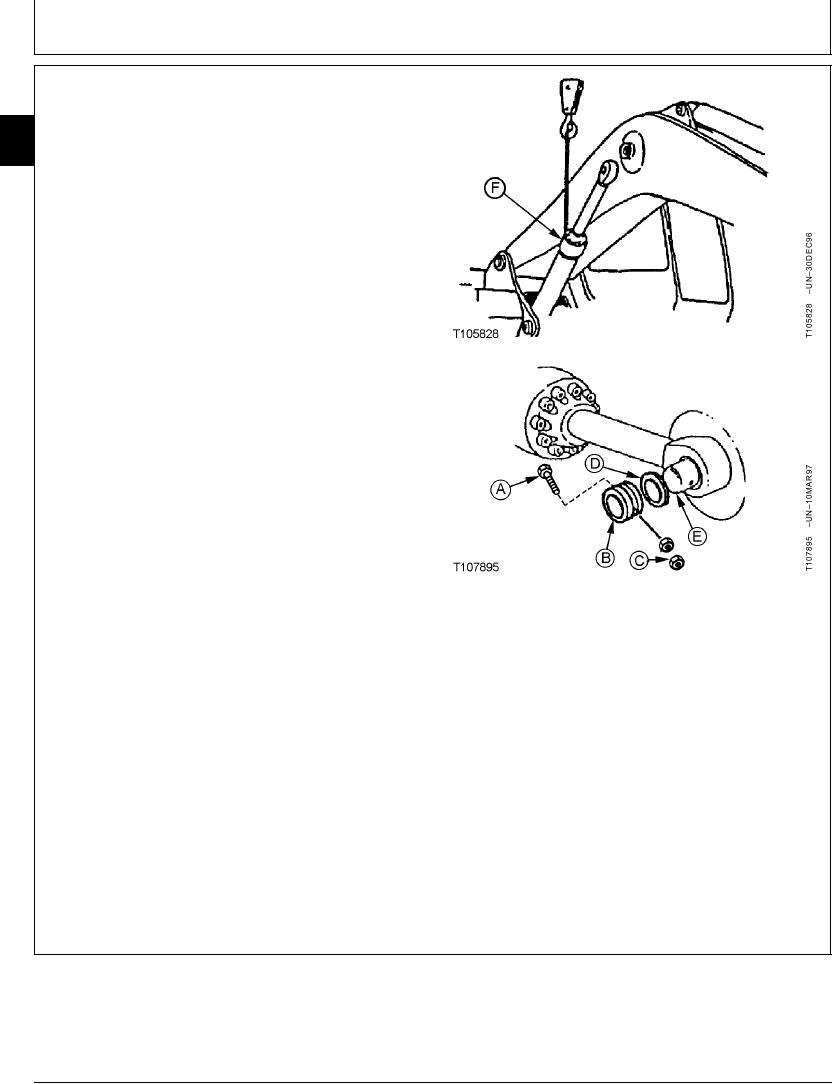

16. Slowly extend boom cylinder (F) to align pin bores so

dust seals are not damaged as cylinder-to-boom pin

(E) is installed.

17. Install shims (D) to get minimum amount of clearance

between boom and cylinder rod end.

Install retainer (B), cap screw (A) and nuts (C).

Tighten nuts against each other, not the retainer. Cap

screw must be free to turn in hole.

Boom Cylinder-to-Boom Pin M20 Cap Screw Nut--Specification

Torque ....................................................... 540 Nm (400 lb-ft) tighten nut

against nut, not the retainer

18. Connect lubricant line.

A--M20 Cap Screw

B--Retainer

C--M20 Nut (2 used)

19. Lubricate all pivot joints. (See Track Adjuster,

D--Shim (As Required)

Working Tool Pivot, Swing Bearing, and Swing

E--Boom Cylinder-to-Boom Pin

Bearing Gear Grease in Group 0004.)

F--Boom Cylinder

20. Bleed air from cylinder. (See procedure in this group.)

21. Check oil level in hydraulic oil tank. Add oil as

necessary. (See Hydraulic Oil in Group 0004.)

CED,OUOE026,9 1918JUN985/5

19-179