TM 5-3805-294-23-1

0003

ELECTRICAL SYSTEM - Continued

65

62

63

64

HYEX01683

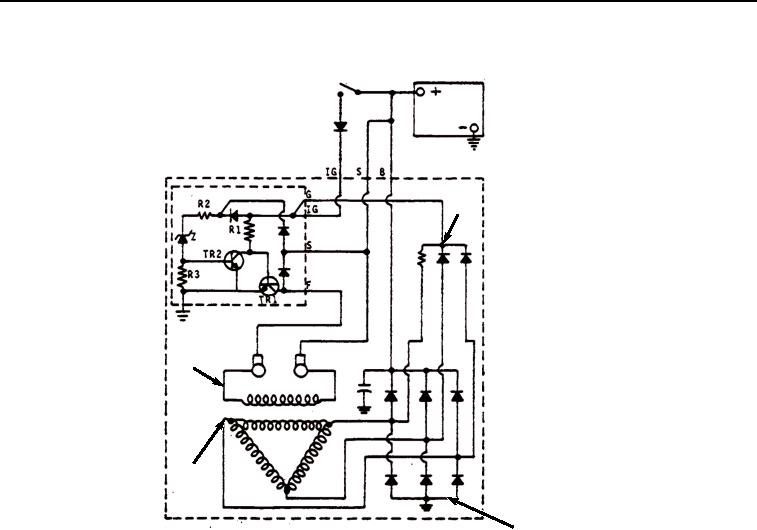

Figure 9. Typical Alternator Operation.

Starter Motor

NOTE

Never operate starter motor longer than 30 seconds. Allow at least 2 minutes for cooling and

battery recovery before operating again. Overheating caused by excessive operation will

seriously damage starter motor.

The starter motor is part of the starting circuit, the starter motor is used to turn the engine flywheel fast enough to

start the engine. The reduction or R-type starter motor is a positive shift type and consists of the motor, reduction

gear, overrunning clutch, and solenoid switch. The solenoid switch and overrunning clutch mechanism are on the

same axis. In a conventional starter motor, the armature and overrunning pinion rotate at the same speed. In a

reduction-type starter motor, the armature rotation is reduced by one-fourth to one-third by the reduction gears, and

is transmitted to the pinion through the clutch mechanism.

When solenoid assembly (Figure 10, Item 66) engages, it pushes overrunning clutch drive (Figure 10, Item 67) to

engage pinion gear (Figure 10, Item 68) in starter gear on flywheel. As armature (Figure 10, Item 69) turns, it cranks

the engine. When engine starts, overrunning clutch drive (Figure 10, Item 67) spins freely on shaft. This prevents

over-speeding of the armature by the flywheel. When the key switch is released, current to the solenoid hold-in

winding is shut off. Current can feed through both the pull-in and hold-in windings from the main contacts, but the

direction of current is reversed in the pull-in winding. The two windings cancel each other, and the solenoid is

released. A spring pushes the solenoid back to disengaged position. This opens the main contacts and shuts off

current to field windings (Figure 10, Item 70) and armature (Figure 10, Item 69). Overrunning clutch drive (Figure

10, Item 67) retracts, disengaging pinion gear (Figure 10, Item 68) from the flywheel.