TM 5-3805-294-23-4

0537

INSPECTION - Continued

2.

Visually inspect lowest points of fittings, hoses, and lines for indication of oil leaks.

END OF TASK

TEST

1.

Air conditioning system must be charged with sufficient amount of refrigerant to have a minimum gauge

pressure of 50 psi (3.44 bar) when not in operation. At temperatures below 59F (15C), leaks may not be

measurable, since pressure may not be reached.

WARNING

Particles blown by compressed air are hazardous. Ensure air stream is directed away from

user and any personnel in the area. Use a maximum of 30 psi (2.0 bar) when compressed

air is used to clean parts. Always wear safety glasses when using compressed air. Failure to

comply may result in injury or death to personnel.

2.

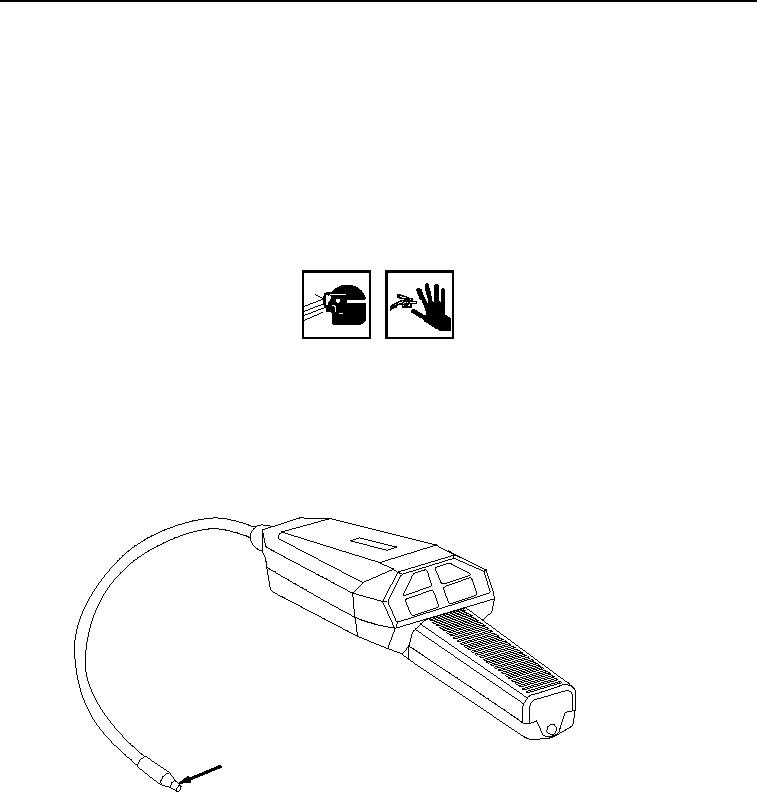

Take care not to contaminate leak detector probe tip (Figure 1, Item 1). If component being tested is dirty or

moisture is present, it should be wiped off with a clean, dry rag, or blown off with compressed air. Do not use

cleaners or cleaning solvents to clean detector. Detector may be sensitive to ingredients in cleaners or cleaning

solvents.

1

HYEX00224

Figure 1. Leak Detector.

3.

Each questionable area must be carefully checked with leak detector probe tip (Figure 1, Item 1). Check all

fittings, hoses, service ports, and areas around cushion clamps and tie wraps.

4.

Always follow air conditioning system in a continuous path to ensure no areas of potential leaks are missed.

If a leak is found, continue to test remainder of air conditioning system.

5.

At each area checked, leak detector probe tip (Figure 1, Item 1) should be moved completely around location

at a rate of no more than 1 - 2 in. (3 - 5 cm)/second, and no further than 1/4 in. (6 mm) from surface. Slower