TM 5-2420-230-24-1

Avoid contact with hot oil. Failure to comply may result in serious injury.

(2)

Position funnel beneath sump plug, remove oil drain plug and washer. Allow oil to drain completely.

b. Replacement.

(1)

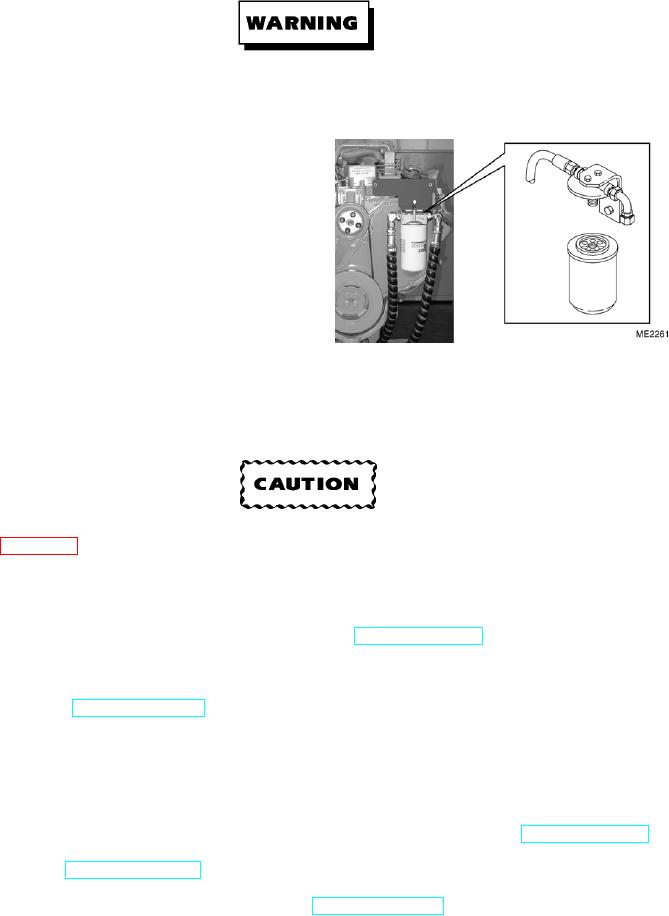

Remove oil filter. Discard oil filter.

(2)

Using a clean cloth, ensure oil filter gasket

surface on mounting head is clean.

(3)

Fill new oil filter with clean lubricating oil and

spread oil on sealing gasket.

(4)

Install oil filter on mounting head and tighten in

accordance with filter manufacturer's

instructions.

c. Filling.

(1)

Inspect condition of sump plug washer. Replace if necessary.

To prevent possible damage to oil sump plug and filter element thread, do not exceed specified torque

(Appendix E). Failure to comply may result in damage to equipment.

(2)

Using a clean cloth, ensure mating surfaces are clean and install sump plug and washer. Tighten to 59 lbf /ft

(80 Nm).

(3)

Add oil to engine until oil reaches FULL mark on dipstick (TM 5-2420-230-10).

d. Follow-On Maintenance.

(1)

Start engine (TM 5-2420-230-10).

(2)

Note oil pressure by checking oil pressure gauge and warning lamp. Lamp should go off after a few seconds. If oil

pressure is not evident after 10 seconds, shut OFF engine and investigate.

(3)

Check oil filter and drain plug for signs of oil leakage.

(4)

Shut OFF engine, wait 5 min., then check oil level with dipstick. Add oil as necessary (TM 5-2420-230-10).

(5)

Close hood (TM 5-2420-230-10).

(6)

Remove "Do Not Operate" tag from ignition switch (TM 5-2420-230-10).

END OF TASK

Change 1

4-3