TM 5-2420-230-24-1

d. Installation.

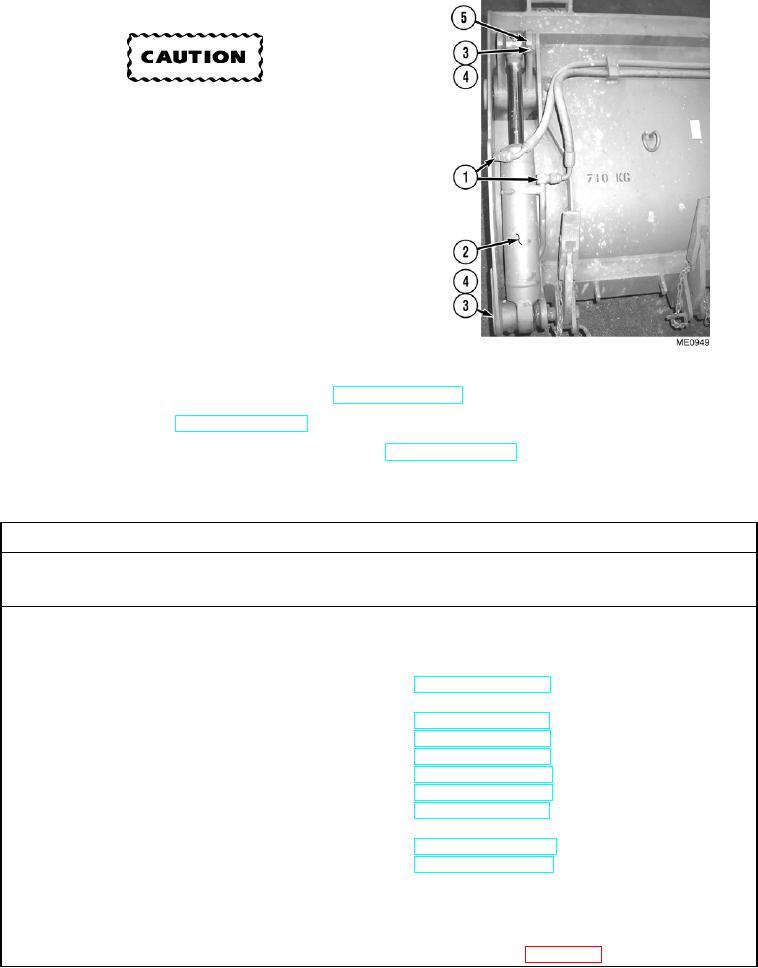

Ensure pins are lubricated before installing.

Failure to comply could result in damage to

equipment.

NOTE

Ensure all hoses and tubes are reconnected to

positions noted prior to removal.

Install cable ties as necessary.

(1)

Install 4-in-1 bucket cylinder (2) with two pivot

pins (5), bolts (4), and new self-locking nuts (3).

(2)

Connect two hydraulic hoses (1) to 4-in-1

bucket cylinder (2).

e. Follow-On Maintenance.

(1)

Start engine and functionally test cylinders (TM 5-2420-230-10).

(2)

Shut OFF engine (TM 5-2420-230-10).

(3)

Remove "Do Not Operate" tag from ignition switch (TM 5-2420-230-10).

END OF TASK

10-26. HYDRAULIC CALIBRATION PROCEDURE.

This Task Covers:

a. Calibration

b. Functional Test

c. Follow-On Maintenance

INITIAL SETUP

Test Equipment

Equipment Conditions

None

TM or Para

Condition Description

Vehicle positioned on level

ground.

Tools and Special Tools

None

Parking brake applied.

Engine shut OFF.

Electrical master switch OFF.

Materials/Parts

None

Travel stops stowed.

Bucket locking clevis removed.

Headlights placed in travel

Personnel Required

MOS 62B, Construction Equipment Repairer

mode.

LOADER mode selected.

BACKHOE A mode selected.

References

FO-4, Hydraulic schematic

Drawings Required

None

Estimated Time to Complete

Refer to MAC in Appendix B

Change 1