TM 5-2420-230-24-1

10-24. TILT LINKAGES REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

c. Follow-On Maintenance

INITIAL SETUP

Test Equipment

Equipment Conditions

None

TM or Para

Condition Description

Bucket in dig position.

Engine shut OFF.

Tools and Special Tools

Field, maintenance, basic, Item 23, Appendix B

Electrical master switch OFF.

Tool kit, general mechanics, Item 38, Appendix B

"Do Not Operate" tag attached

Equipment, suitable lifting

to ignition switch.

Materials/Parts

Drawings Required

Grease, automotive and artillery, Item 30, Appendix C

TM 5-2420-230-24P Figure 161

Nut, self-locking, Item 114, Appendix D

Estimated Time to Complete Task

Refer to MAC in Appendix B

Personnel Required

MOS 62B, Construction Equipment Repairer

References

None

a. Removal.

NOTE

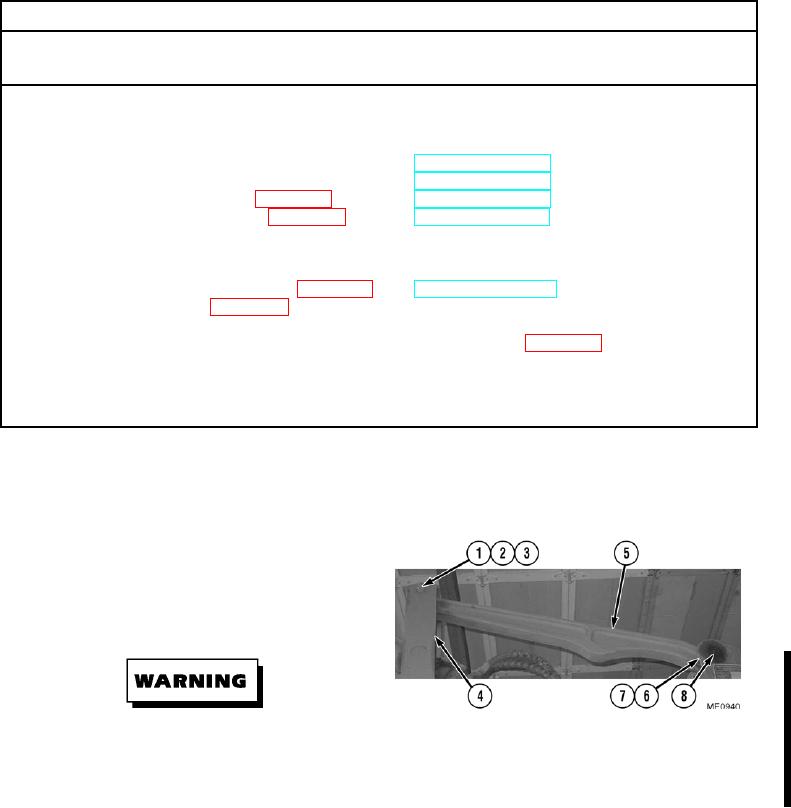

Both tilt linkages are removed and installed in the same way. Right side is shown.

(1)

Remove self-locking nut (1), bolt (2), and

washer (3) from pivot arm (4) and tilt

linkage (5). Discard self-locking nuts.

(2)

Remove nut (6) and bolt (7) from pivot

pin (8).

Tilt linkages are heavy. Use an appropriate

lifting device and follow safe working

procedures when lifting or moving tilt

linkages. Failure to comply may result in

injury or death to personnel.

(3)

Attach suitable lifting device and sling to tilt linkage (5).

(4)

Remove pivot pin (8) from tilt linkage (5). Remove tilt linkage.

Change 1