TM 5-2420-230-24-1

b. Installation.

Ensure pins are lubricated before installing. Failure to comply could result in damage to equipment.

NOTE

Ensure all hoses and tubes are reconnected to positions noted prior to removal.

Install cable ties as necessary.

(1)

Install fittings if necessary.

(2)

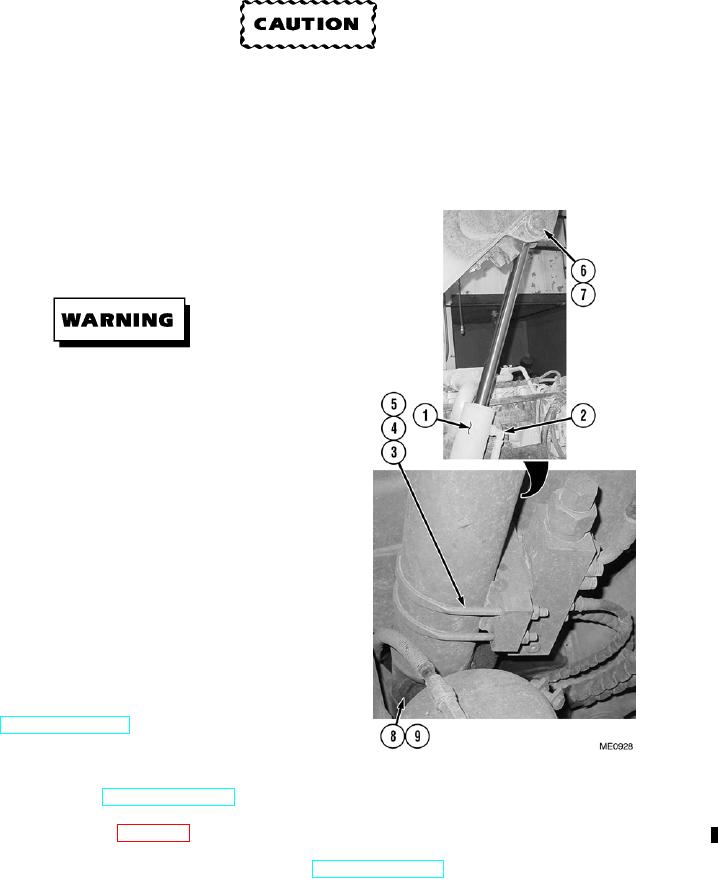

Attach suitable lifting device and sling to FEL

lift cylinder (1).

Use care when removing or installing snap and

retaining rings. Snap and retaining rings are

under spring tension and can act as projectiles

when released and could cause severe eye injury.

(3)

Use lifting device to position FEL lift

cylinder (1) and travel stop, and install with top

pivot pin (7), top circlip (6), bottom pivot

pin (9), and bottom circlip (8).

(4)

Remove cable ties securing check valve, and

install on FEL lift cylinder (1) with two

washers (5), nuts (4), and U-bolts (3).

(5)

Connect hydraulic hose (2) to FEL lift

cylinder (1).

c. Follow-On Maintenance.

(1)

Start engine and functionally test cylinders

(2)

Check for leaks.

(3)

Shut OFF engine (TM 5-2420-230-10).

(3.1) Install front fender (Para 13-16).

(4)

Remove "Do Not Operate" tag from ignition switch (TM 5-2420-230-10).

END OF TASK

Change 1

10-49