TM 5-2420-230-24-1

a. Draining.

Ensure air pressure is drained to 0 psi (0 kPa) before taking off any air components. If pressure is not

released, components could blow off and harm personnel. The IHMEE air system is pressurized to

119 psi (820 kPa). Do not drain air from a tank with any part of body in air spray path. Skin embolisms

and/or debris in eyes can occur from released pressure. Failure to comply may result in injury or death

to personnel.

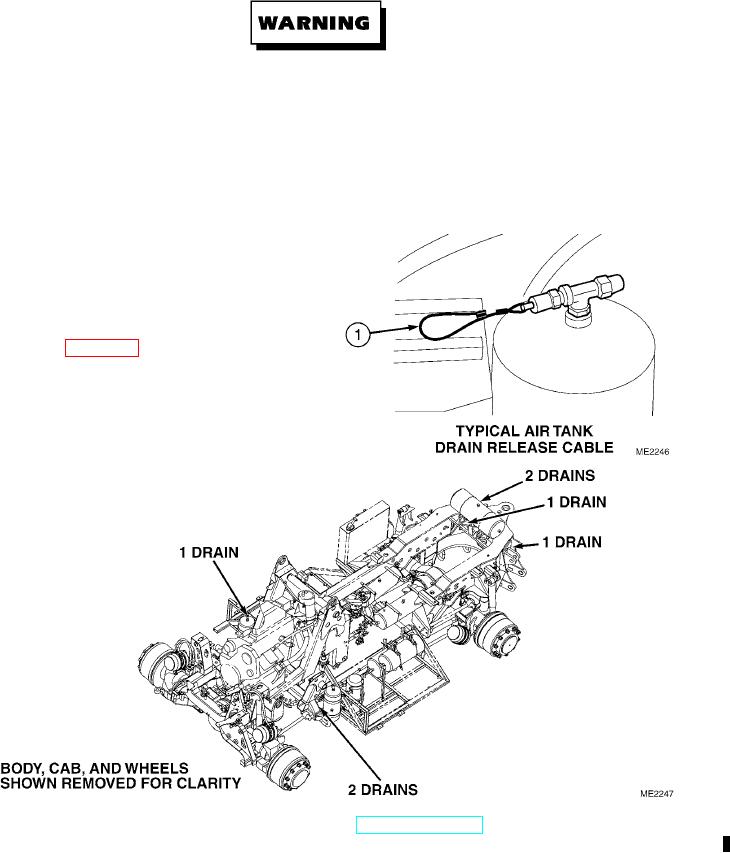

NOTE

All pneumatic tanks have a drain valve supplied with a pull cable of type used to drain the system.

(1)

To drain the system, pull on seven release air

tank cables (1) until all air has been released.

NOTE

Excessive moisture indicates a defective air

drier, which must be replaced as soon as

possible (Para 15-11).

(2)

Place drain pan under air tanks when air is

being drained. Inspect drain pan for

moisture.

b. Inspection.

(1)

Examination of air tanks requires removal of belly plates (TM 5-2420-230-10) to gain access and visually inspect

air tanks for the following:

Damage, loose fittings, and mountings

Air leaks; use leak-detecting liquid

Corrosion

Change 1

15-3