TM 5-2420-230-24-1

6-10. SWAY BAR REPLACEMENT.

This Task Covers:

a. Removal

b. Inspection

c. Installation

d. Follow-On Maintenance

INITIAL SETUP

Test Equipment

Equipment Conditions

None

TM or Para

Condition Description

Vehicle positioned on level

ground.

Tools and Special Tools

Tool kit, common no. 2, Item 36, Appendix B

Parking brake applied.

Tool kit, general mechanics, Item 38, Appendix B

Engine shut OFF.

Electrical master switch OFF.

"Do Not Operate" tag attached

Material/Parts

Nut, self-locking, Item 123, Appendix D (4)

to ignition switch.

Nut, self-locking, Item 125, Appendix D (4)

Washer, lock, Item 282, Appendix D (4)

Drawings Required

TM 5-2420-230-24P Figure 119

Personnel Required

MOS 62B, Construction Equipment Repairer (2)

Estimated Time to Complete

Refer to MAC in Appendix B

References

None

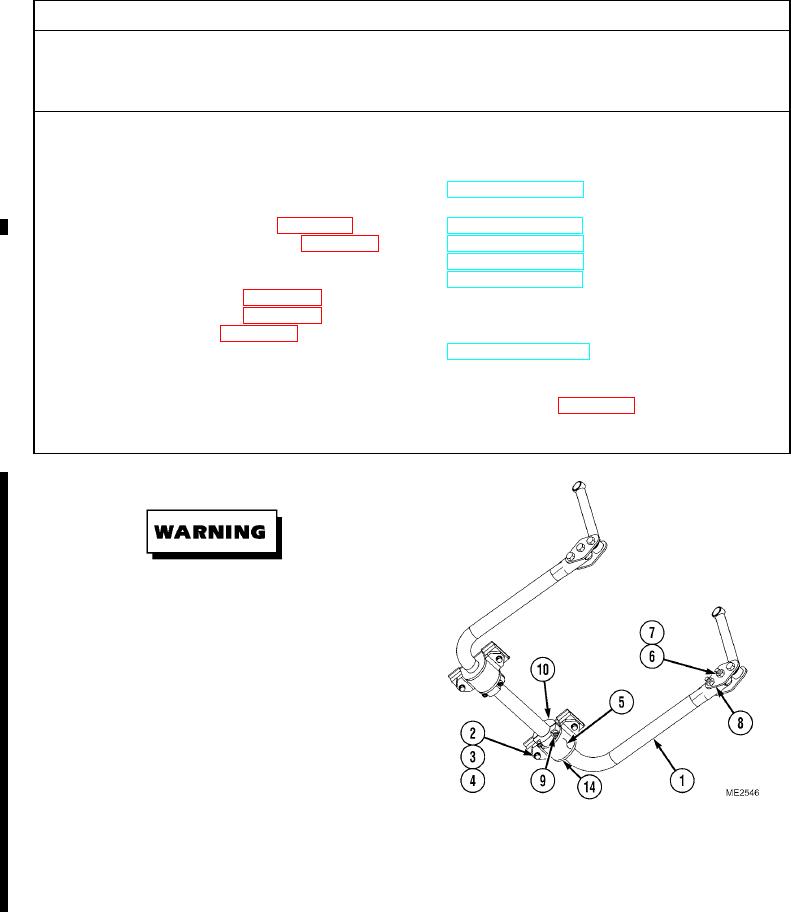

a. Removal.

The sway bar is heavy and it is under tension

when installed. To prevent injury, take care when

removing and installing sway bar. Failure to

comply may result in injury or death to

personnel.

(1)

Place jack under center of sway bar (1) and raise

jack to support weight of sway bar.

(2)

Remove four bolts (2), washers (3),

lockwashers (4), and two sway bar supports (5)

from vehicle. Discard lockwashers.

(3)

Carefully lower jack.

(4)

Support sway bar (1) and remove four bolts (6) and self-locking nuts (7) from connecting arms (8). Discard self-

locking nuts.

(5)

Remove four screws (9) from two split collars (10), and remove split collars from sway bar (1).

Change 1