TM 5-2420-230-24-1

b. Installation.

Adhesives, solvents, and sealing compounds burn

easily and give off vapors that are harmful to the

skin and clothing. To avoid injury or death, keep

away from open fire when using these materials,

and use only in well-ventilated areas. If adhesives,

solvents, or sealing compounds contact the skin or

clothing, wash immediately with soap and water,

and rinse thoroughly. Failure to comply may result

in injury or death to personnel.

NOTE

Install cable ties as necessary.

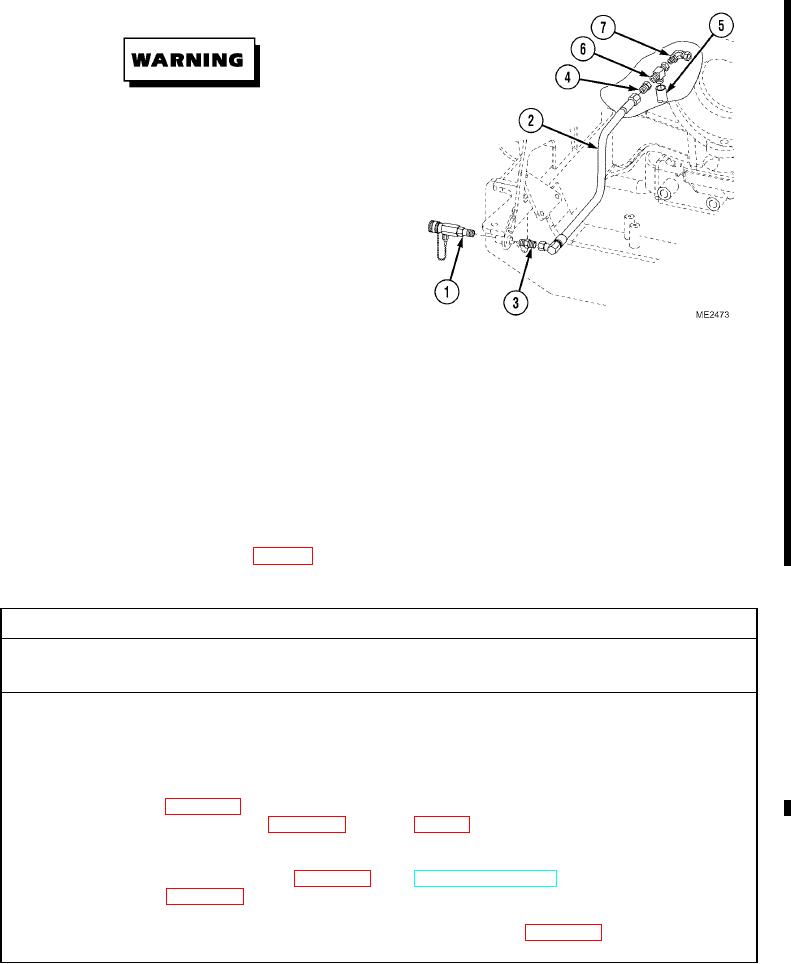

Orient the T-fitting (6) toward the rear of the machine.

(1)

If removed, apply sealing compound and install elbow (7), T-fitting (6), reducer (4), hose (5), and adaptor (3) on

vehicle.

(2)

If removed, install hose (2) on reducer (4) and adaptor (3).

(3)

Apply sealing compound and install oil sampling valve (1) on vehicle.

c. Follow-On Maintenance.

Fill engine oil and check for leaks (Para 4-4).

END OF TASK

4-13. TRANSMISSION OIL SAMPLING VALVE ASSEMBLY REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

c. Follow-On Maintenance

INITIAL SETUP

Test Equipment

References

None

None

Tools and Special Tools

Equipment Conditions

Pan, drain, Item 29, Appendix B

TM or Para

Condition Description

Tool kit, general mechanics, Item 38, Appendix B

Transmission oil drained.

Materials/Parts

Drawings Required

Compound, sealing, pipe thread, Item 23, Appendix C

TM 5-2420-230-24P Figure 157

Ties, cable, Item 68, Appendix C

Estimated Time to Complete

Refer to MAC in Appendix B

Personnel Required

MOS 62B, Construction Equipment Repairer

Change 1