TM 5-3805-294-23-1

0003

POWER TRAIN

Power Train Operation

On the HYEX, a solenoid is activated when pressure is sensed at the travel pressure sensor, the swing pressure

sensor is not sensing pressure (no front attachment pressure sensor functions activated), either pump delivery

pressures are low, and either control pressures are high. Activation of the travel speed solenoid sends pilot pressure

to the travel speed change valve in the travel motors. Pressure at the travel speed change valve changes the

displacement of the travel motors allowing for fast travel speed. Since either delivery pressure may be low and either

control pressure may be high, the travel motor will shift speeds even if the other motor is stationary. If the machine

is travelling in fast travel speed and a dig or swing function is operated, the machine will remain in fast travel speed,

but will slow in travel speed as hydraulic oil is routed to other functions.

Tracks/Adjuster/Rollers

The track assembly consists of the chain and shoes. The travel motor drives the track to move the HYEX.

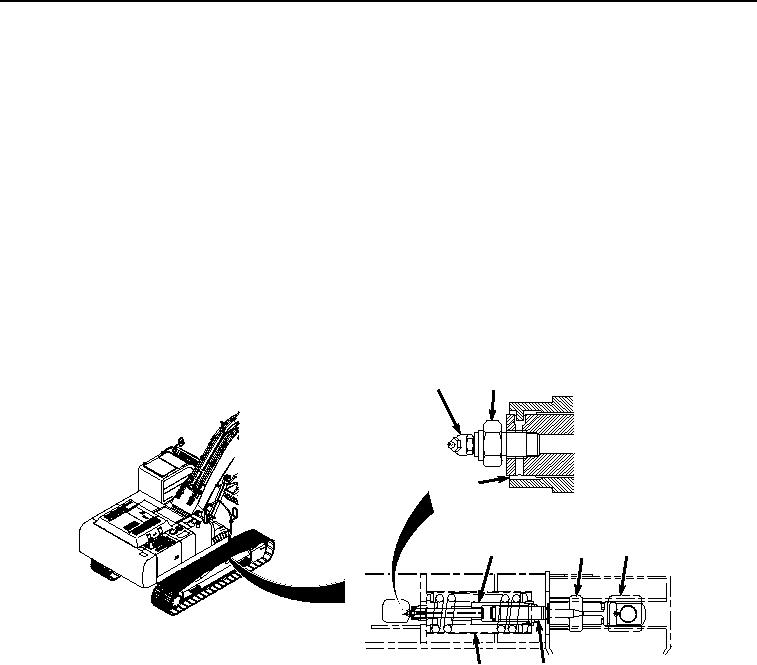

The track adjuster and recoil spring (Figure 16, Item 106) are supported by the track frame. Shock loads on the track

and front idler (Figure 16, Item 107) are absorbed by the recoil spring.

112

109

113

108

111

107

106

110

HYEX01691

Figure 16.

Track Adjuster and Recoil Spring Assembly Operation.

To decrease track sag, pump grease into cylinder (Figure 16, Item 108) through grease fitting (Figure 16, Item 109).

The grease pushes the piston (Figure 16, Item 110) against the yoke (Figure 16, Item 111), moving the front idler

(Figure 16, Item 107) out, and reducing track sag. The grease fitting (Figure 16, Item 109) is protected from excess

pressure by a check ball. Increasing track sag is accomplished by loosening the nut (Figure 16, Item 112) to release

grease from the cylinder (Figure 16, Item 108) through the concealed grease relief passage (Figure 16, Item 113).

When releasing grease from the cylinder, only loosen the nut (Figure 16, Item 112).

The HYEX has two carrier rollers (Figure 17, Item 114) and nine lower track rollers (Figure 17, Item 115) on each

side of the machine. The rollers guide the tracks (Figure 17, Item 116) and keep the tracks in contact with the ground.